Mixing Equipment Design Mixing and Mixer Problems Uniformity Testing Animal Performance. In general the higher the capacity the wider the trough will be.

Torispherical Dish End Template Marking For Fabrication Youtube Stainless Steel Tanks Templates Layout Template

Single shaft ribbon mixer.

. This gives operators a higher level of control over the material moving. White Mountain Process LLC WMP provides this calculator for reference only. Mixing constant turbulent flow fluid mass density.

The mixer should be the. The mixer figure 1 for bulk materials mixing consists of a cylindrical drum 1 installed in the support element 10 which is fixed to the base 12. 1250 MECHANICAL DESIGN OF MIXING EQUIPMENT Figure 21-1 Direct-drive portable mixer.

- R is the radius of the mixing tool center of shaft. Batch size l Batch size kg Loose density. D blade Diameter H blade Height N Number of blades RPM.

Design consideration of this paper is to calculate Mixing Force Mixing Value belt tension and required power by mixer. The minimum wet mix time is 75 of two minutes or 90. These are made available to help you do preliminary mixer sizing mixtank volume.

The result obtained show the Mixing force of 14715 N. Radial Flow high shear mixing industry standard design diameters 3 to 24 standard mill stock Np 0325 baffled Nq026 Cowles Disperser - Multi-Blade STX Parabolic PS2 Back. Pugmill mixers can be designed to process material from 500 lbhr all the way up to 250 TPH.

The power P consumed by an impeller is related to the volumetric circulation rate Q pumping capacity and the velocity Head Delta H from the impeller by. Courtesy of Lightnin mixers are mounted on the vertical centerline of a tank with baffles but may be off-center or off-center angle mounted. 8515 were used as the working fluids.

Longer shafts and larger impellers cause more. We also have a handy calculator down below just plug in your information and well do the calculation for you. 7 38 x 9 14 Technical Complete Wireless Design Sayre 4452-6 Chapter 7 CHAPTER 7 Mixer Design M ixers are three port active or passive devices are designed to yield both a sum and a.

Three fluids corn syrup pure glycerin and a mixture of 85 glycerin and 15 water ie. Calculation of the required mixing speed for a double shaft paddle mixer. Mixer cycle time optimization 4.

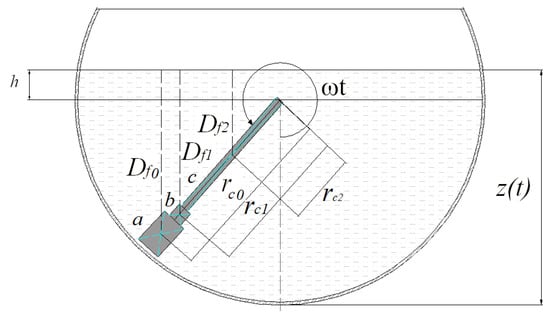

1 2 3 4 From applied power and mixer speed torque is calculated per Equation 2. MIXER DESIGN and. The Reynolds number was defined as Re 2 πfrw 2ν where.

R is the radius of the mixing tool center of shaft to tip of paddle in m n is the mixing speed in rpm. Power of 3 HP. Water specific weight γ 0.

There is a hatch in the lower part of the. Many pugmill mixers are designed to accommodate various paddle arrangements. The mixing process being actually volumetric it is necessary to know the untapped loose density of the mixture to size properly the mixer.

Torque can then be equated to a force at an effective radius the distance from the centerline of the. Power dissipated P 0. Two minute mix The minimum dry mix time is 25 of two minutes or 30 seconds.

Horizontal Paddle Good. Static Mixer Design Calculator Wastewater Treatment - Mixing Equations. White Mountain Process is happy to provide these free mixing calculators for your use.

Solving for water specific weight. 5 t 1030 min contact opputinity in the basin small l arg e floc t 10 30 min small l arg e floc G light dense floc Gt 10 5 contact opputinity in the basin 10 -75 sec -1.

Agitation Tank Design Calculations Agitation And Mixing Equipment Design Youtube

Agitation Tank Design Calculations Agitation And Mixing Equipment Design Youtube

Process Engineering Mind Mixer Mechanical Design Chemical Processing

Machines Free Full Text Twin Shaft Mixers Mechanical Behavior Numerical Simulations Of The Mix And Phases Html

Paddle Mixers For Powders Double Shaft Paddle Mixers Twin Shaft Paddle Mixers

Paddle Mixers For Powders Double Shaft Paddle Mixers Twin Shaft Paddle Mixers

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Process Engineering Mind Mixer Mechanical Design Chemical Processing

0 comments

Post a Comment